Crimp Pump

Crimp Pump Specification

- Product Type

- Crimp Pump

- Material

- Glass

- Sealing Type

- Easy Open End

- Industrial Use

- Beverage, Chemical, Oil, Pharmaceutical

- Shape

- Round

- Height

- 25.4 - 50.8 Millimeter (mm)

- Color

- White And Golden

Crimp Pump Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Supply Ability

- 5000 Pieces Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Crimp Pump

Our company, H. N. G. Glass Factory, has been indulged in manufacturing and supplying an excellent array of Crimp Pump. This pump is light weighted and is designed by our engineers with utilization of modern machines. Offered pump is widely used for fragrance and perfume products. It is designed with utmost precision and care to ensure its accurate dimension and shape. Produces small amount of liquid, Crimp Pump pushes small amounts of liquid over a large surface area to help spread the minute liquid contents. It is manufactured by using excellent grade materials that are procured from esteemed vendors.

Versatile Industrial Applications

Our Crimp Pumps are utilized across a spectrum of industries, including beverage, pharmaceutical, chemical, and oil sectors. Their adaptable design ensures compatibility with diverse liquid products and applications, making them suitable for stringent industrial requirements. The glass construction provides excellent resistance to chemicals and preserves product integrity, while the round shape allows for seamless integration into existing process lines.

Superior Material and Sealing Technology

Crafted from premium glass, these crimp pumps offer highly reliable performance and durability. The easy open end sealing type enhances user convenience, ensuring quick access and secure closure for a variety of fluids. The white and golden finishes not only enhance visual appeal but also signify quality and attention to detail, making them stand out in industrial settings.

FAQ's of Crimp Pump:

Q: How are Crimp Pumps typically used in industrial settings?

A: Crimp Pumps are primarily used for dispensing, transferring, and storing liquids in industries such as beverage, chemical, oil, and pharmaceuticals. Their robust design supports consistent and accurate pumping, making them ideal for both automated and manual operations.Q: What benefits do glass Crimp Pumps offer compared to other materials?

A: Glass Crimp Pumps provide excellent chemical resistance, preventing product contamination. They also maintain the purity and taste of beverages or pharmaceuticals, and can withstand a wide range of temperatures, making them highly durable for industrial use.Q: When should I opt for a Crimp Pump with an easy open end sealing type?

A: Crimp Pumps with easy open ends are preferred when frequent access and secure sealing are required, such as in production lines that involve quick refilling, sampling, or quality checks. This feature streamlines operations and reduces downtime.Q: Where can your Crimp Pumps be exported or supplied from?

A: As a leading exporter, manufacturer, and supplier based in India, we provide Crimp Pumps to clients worldwide, catering to the diverse needs of various industries with prompt delivery and reliable service.Q: What is the process for ordering Crimp Pumps in different sizes and colors?

A: Customers can place orders by specifying their required height (between 25.4-50.8 mm), color preference (white or golden), and quantity. Our team will guide you through selection, customization (if needed), and shipping details.Q: How do the shape and finishing of your Crimp Pumps contribute to their industrial efficiency?

A: The round shape ensures uniform pressure distribution during crimping and facilitates smooth flow within systems. The white and golden finishes help in quick identification and standardization, aiding operational efficiency in fast-paced industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

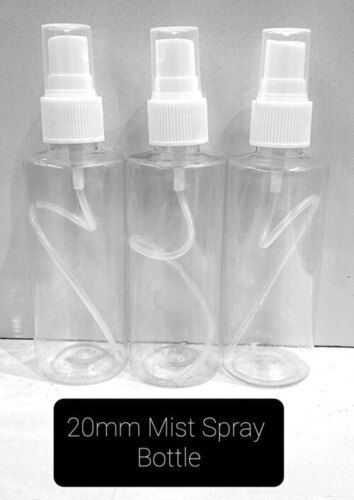

More Products in Fine Mist Sprayer Category

18-20-24-25-28 mm mist spray

Price 2 INR / Piece

Minimum Order Quantity : 10000 Pieces

Sealing Type : Pump Sprayer

Material : Plastic

Product Type : PET Bottle

Fine Mist Sprayer

Price Range 2.00 - 5.00 INR

Minimum Order Quantity : 5000 Pieces

Sealing Type : Easy Open End

Material : Glass

Product Type : Fine Mist Sprayer, Other

|

FANCY BOTTLE INTERNATIONAL PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry